Last month, Gurgaon-based Syrma SGS Technology, an electronics manufacturing services (EMS) firm, signed up with Arch Systems of the US to bring AI into its factories. Syrma SGS has 14 factories manufacturing industrial, automotive, medical and consumer electronics products. AI is expected to help improve production life cycle times, quality, and efficiency.

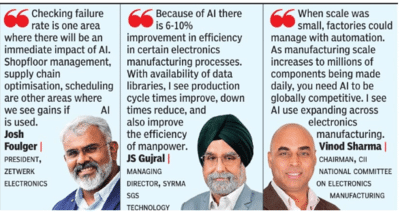

“Earlier, data, the raw material for AI, was not available in a usable form. Now, with real-time data, AI kicks in to improve operations,” says JS Gujral, managing director of Syrma SGS Technology.

EMS companies have long used automation and robotics to improve operations and handle repetitive tasks like welding and on assembly lines. Now, thanks to sensors on every device generating millions of data points, AI is coming in to also make factories 'intelligent’.

“AI is needed to separate the good from the bad,” says Vinod Sharma, MD of Noida-based Deki Electronics, one of the largest capacitor manufacturers in the country. He adds: “When the scale was small, say 100,000 units a day, you could do with automation. But now, as manufacturing scales up to like 1 million parts per day, that needs intelligence in factory operations.”Surface-mount technology (SMT) machines that place components on circuit boards have been used for decades. Now, Josh Foulger, president of Zetwerk Electronics, says computer vision models can detect whether a chip has been placed correctly or if solder is done right. “The algorithms improve yields,” he says.

Such improvements are vital, given that electronics manufacturing runs on low single digital margins. For Foulger, who began working on neural networks and robotics in the 1990s, the leap is significant. He sees AI being used to shave hours off production cycles, optimise shop floors, and reshape supply chains.

Zetwerk Electronics has seven factories, four in Delhi-NCR. Last month, it manufactured about four million devices for top global brands. AI, Foulger says, can unlock “double-digit gains” if applied to scheduling and workflow optimisation, given that factories now rely on human judgment for what to produce, in what order, and with what skills.

Intelligence in every step

At Syrma, Arch Systems’ AI is being rolled out across multiple SMT lines. Each line now tracks rated capacity, actual capacity, downtime, identifies defects, does preventive maintenance and checks causes of production delays, if any. “If say 35 machines run for 20 hours (in a 24-hour cycle), that’s a total of 700 hours. Even a 5% improvement gives me 35 extra hours daily. Over a month, that’s like adding an extra line,” Gujral says.

AI is bringing efficiency to the ₹request for quote’ (RFQ) process. A product like a smartphone, laptop, or digital camera, could have 500 parts. What parts are already with the company, what has to be ordered at what cost and from where was mostly a manual process. Now the 'quote cell’ (an estimate of cost) is linked to the SAP database via a customised AI that will automatically generate an optimum bill of materials (BoM).

Earlier, if a component distributor quoted 15 cents per component while it was available for 10 cents in some global markets, manufacturers in India would not know and start negotiating at 15 cents. “While I might go from 15 to 13 cents, a global manufacturer goes from 10 to 7 cents. Now, AI is making us globally competitive,” says Gujral.

Sharma of Deki Electronics, which makes millions of capacitors daily, says if a factory is doing six million welding joints per day for an automobile component, the auto maker wants to know the power (current) tolerances tracked to within one ampere. “AI can be very useful for such applications,” he says.

“Earlier, data, the raw material for AI, was not available in a usable form. Now, with real-time data, AI kicks in to improve operations,” says JS Gujral, managing director of Syrma SGS Technology.

EMS companies have long used automation and robotics to improve operations and handle repetitive tasks like welding and on assembly lines. Now, thanks to sensors on every device generating millions of data points, AI is coming in to also make factories 'intelligent’.

“AI is needed to separate the good from the bad,” says Vinod Sharma, MD of Noida-based Deki Electronics, one of the largest capacitor manufacturers in the country. He adds: “When the scale was small, say 100,000 units a day, you could do with automation. But now, as manufacturing scales up to like 1 million parts per day, that needs intelligence in factory operations.”Surface-mount technology (SMT) machines that place components on circuit boards have been used for decades. Now, Josh Foulger, president of Zetwerk Electronics, says computer vision models can detect whether a chip has been placed correctly or if solder is done right. “The algorithms improve yields,” he says.

Such improvements are vital, given that electronics manufacturing runs on low single digital margins. For Foulger, who began working on neural networks and robotics in the 1990s, the leap is significant. He sees AI being used to shave hours off production cycles, optimise shop floors, and reshape supply chains.

Zetwerk Electronics has seven factories, four in Delhi-NCR. Last month, it manufactured about four million devices for top global brands. AI, Foulger says, can unlock “double-digit gains” if applied to scheduling and workflow optimisation, given that factories now rely on human judgment for what to produce, in what order, and with what skills.

Intelligence in every step

At Syrma, Arch Systems’ AI is being rolled out across multiple SMT lines. Each line now tracks rated capacity, actual capacity, downtime, identifies defects, does preventive maintenance and checks causes of production delays, if any. “If say 35 machines run for 20 hours (in a 24-hour cycle), that’s a total of 700 hours. Even a 5% improvement gives me 35 extra hours daily. Over a month, that’s like adding an extra line,” Gujral says.

AI is bringing efficiency to the ₹request for quote’ (RFQ) process. A product like a smartphone, laptop, or digital camera, could have 500 parts. What parts are already with the company, what has to be ordered at what cost and from where was mostly a manual process. Now the 'quote cell’ (an estimate of cost) is linked to the SAP database via a customised AI that will automatically generate an optimum bill of materials (BoM).

Earlier, if a component distributor quoted 15 cents per component while it was available for 10 cents in some global markets, manufacturers in India would not know and start negotiating at 15 cents. “While I might go from 15 to 13 cents, a global manufacturer goes from 10 to 7 cents. Now, AI is making us globally competitive,” says Gujral.

Sharma of Deki Electronics, which makes millions of capacitors daily, says if a factory is doing six million welding joints per day for an automobile component, the auto maker wants to know the power (current) tolerances tracked to within one ampere. “AI can be very useful for such applications,” he says.

You may also like

BTSC Work Inspector Vacancy 2025: Recruitment for 1114 Work Inspector posts announced in Bihar, applications will start from October 10..

Myanmar festival bombing: Dozens killed in horror paraglider raid at major event

Dolly Parton's furious response after sister asks for prayers

India U19 Thump Aus U19 Inside Two Days In Second Youth Test, Sweep Series 2-0

Rajvir Jawanda dead: Beloved singer dies at 35 after horror accident left him on life support